Stop Wasting Your Machine Time.

Start Running Your Production Floor From Your Office.

Up and running in 2 days

Yes, that’s all it takes. Our engineer needs only 2 working days to configure and install the software on your workfloor, and provide the necessary things.

As easy as printing on PC

Makes piloting CNC machines as easy as printing a document from a PC. Run your production workfloor from your office.

Lifetime guarantee

We are your loyal, reliable partner. This is our guarantee: your macros will be working, no matter the change in the configuration. If- anytime in future – you buy a new machine, type of profile or construction software you have a problem with your macros, we will simple come and fix your problem.

Up and running in 2 days

Yes, that’s all it takes. Our engineer needs only 2 working days to configure and install the software on your workfloor, and provide the necessary things.

As easy as printing on PC

Makes piloting CNC machines as easy as printing a document from a PC. Run your production workfloor from your office.

Lifetime guarantee

We are your loyal, reliable partner. This is our guarantee: your macros will be working, no matter the change in the configuration. If- anytime in future – you buy a new machine, type of profile or construction software you have a problem with your macros, we will simple come and fix your problem.

500+ Customers Can’t be Wrong

From small and medium, to big international profile production companies, we have more than 500 customers all over Europe.

Jan Ballast is responsible for the automation of the machines of the company Rollecate in the Netherlands. His responsibility is to get the highest efficiency out of different machines in different locations. Here is the opinion of an advanced Uni_Link user.

Rollecate decided to implement the Uni_Link platform for the following reasons:

- All CNC machines are managed from one total solution

- Flexible machine planning. Makes changing planning easy

- Easy and user friendly programming of machine operations

- By means of WYSIWYG 3D visualisation strong reduction of failures and consequential costs

- Fast exchange of complex operations by vector based programming

- Piloting machining centers of many different machine manufacturers available

- Tailor made solutions possible to deal with custom specific needs

- Data import from various construction software available

Jan Ballast

Head of Data Management

Rollecate Netherlands

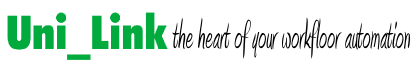

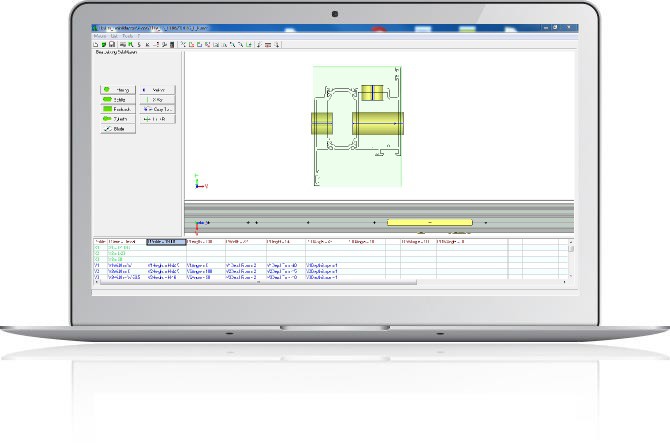

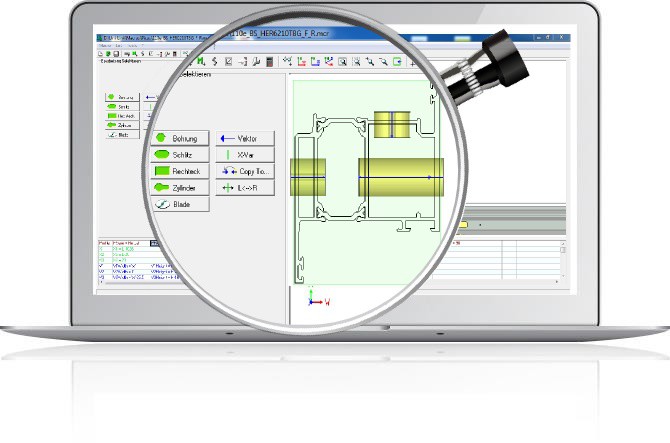

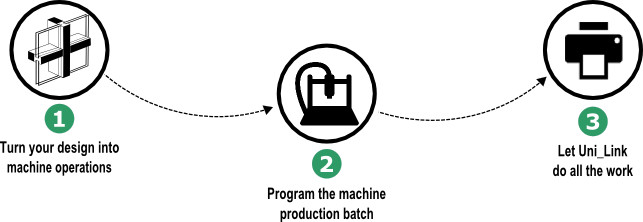

Uni_Link Product Tour

Uni_Link makes manufacturing of designs from ANY construction software on ANY machine as easy as printing a document from a PC. Here is how it works.

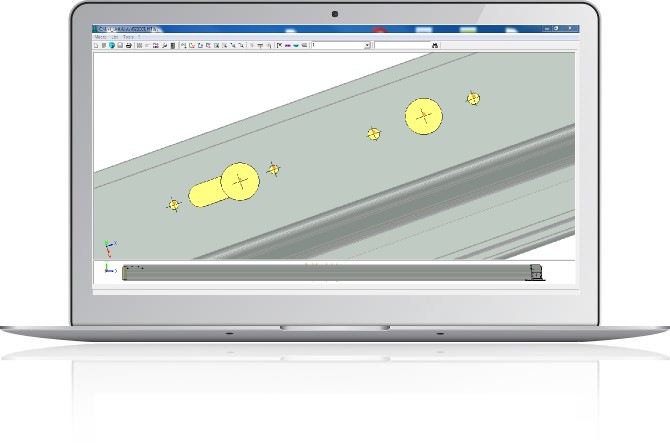

Step 1: Turn Your Design into Machine Operations

Option 1. Uni_Link 1-Click Design Import: simply import your design from any construction software. See – in realistic 3D – all the profile operations before you send them to the machine Option 2: Define Operations Yourself in Uni_Link 3D Visual Operations Designer: the software is so easy to use, we had a 6 year old girl program machines to cut flower patterns. What you see is really what you get. In 3D. You tell Uni_Link WHAT the machine needs to do – not how. Just drag and drop patterns to be cut or drilled onto a profile. Regardless of the machine. Pick operations from our extensive library, or reuse your own operations by simple copy and paste.

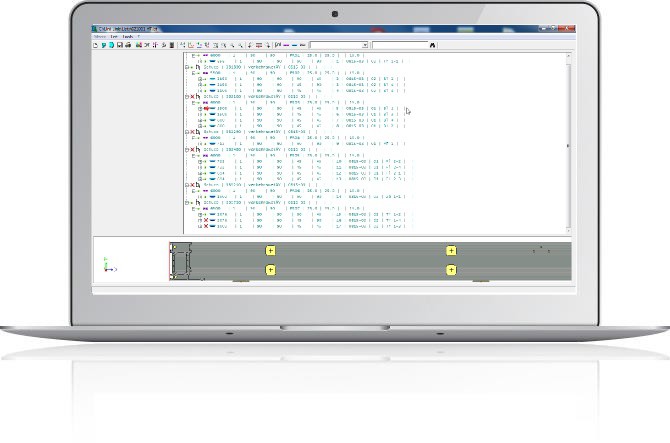

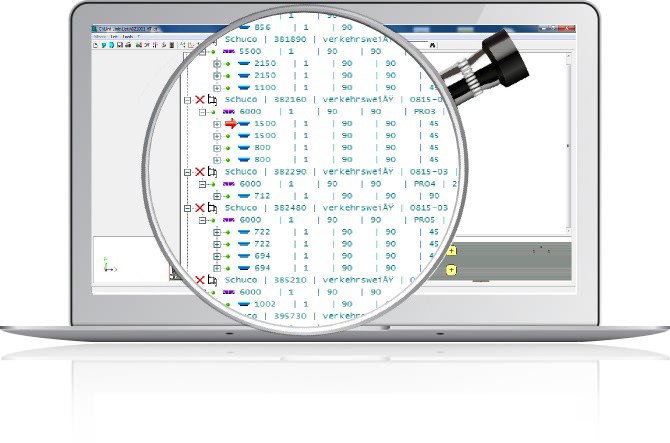

Step 2: Program the Machine Production Batch

Import the list of aluminium profile pieces you have (we support them all). Then just pick operations defined in Step 1 to apply to pieces. Let Un-Link optimize the use of available material – can save up to 30% of your material cost! Uni_Link algorithms detect collisions and prevent any damage of machine tooling or pieces. Guaranteed. That’s all: your machine production batch is ready!

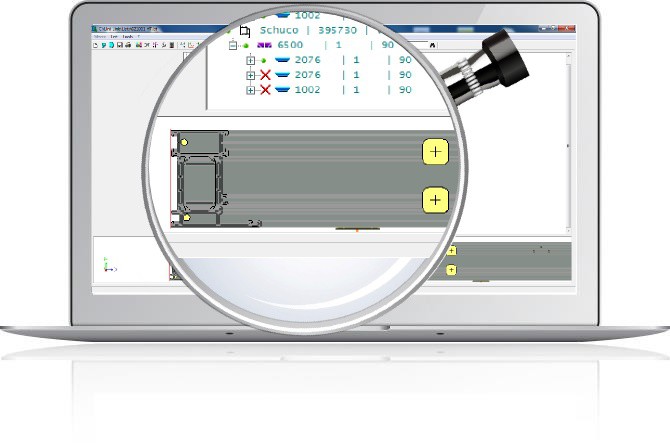

Step 3: Sit Back and Let Uni_Link do all the work

The pieces are cut in the most optimal schedule. You don’t have to do anything, Uni_Link tells the machine exactly how to cut each piece. Each cut piece gets a unique CNC bar code. A simple bar code scan on your CNC machine will immediately program the machine to prepare your piece. All that is left to do is to assemble your products – easier than IKEA furniture

Too good to be true?

Book a free demo to see it with your own eyes. See Uni_Link in Action

Is Your Machine/Software Supported?

Check for yourself if your specific machine/construction software combination is supported.

Our guarantee : Your Uni_Link program will keep on working, no matter the change in your production. If – any time in future – you buy a new machine, type of profile or construction software and encounter any problem, we will simply come and fix it. No questions asked.